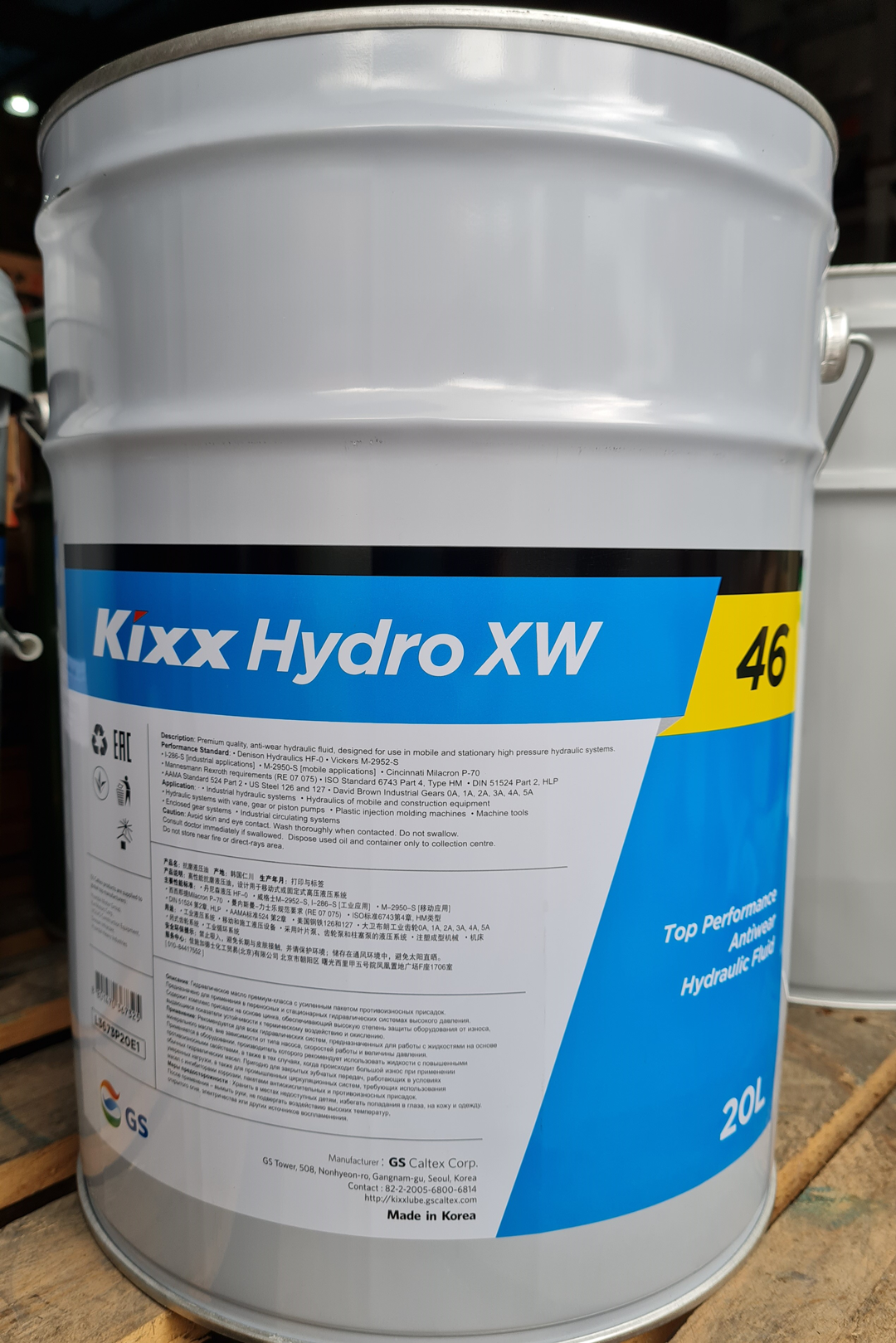

Application

• Industrial Hydraulic systems with vane, gear or piston pumps

• Enclosed gears operating under moderate load conditions

• Industrial circulating systems where a rust and oxidation inhibitor or antiwear oil is required

Performance standards

• ASTM D6158(VG 32, 46, 68, 100, 150)

• DIN 51524 Part 2 HLP(VG 32, 46, 68, 100, 150)

• GB 11118.1-2011, L-HM(VG 32, 46, 68, 100, 150)

• Bosch Rexroth RDE 90245(VG 32 ,46, 68)

• GM Hydraulic Anti-Wear(VG 32, 46, 68)

• SAE MS 1004 HM(VG 32, 46, 68, 100)

• AIST 126, 127(VG 32,46,68,)

• Parker Denison TP30560 HF-0, HF-1, HF-2(VG 32, 46, 68)

• Fives Cincinnati Machine P68(VG 32)/P70(VG 46)/P69(VG 68)

• JCMAS P041 HK Normal Temperature(VG 32, 46)

• Eaton E-FDGN-TB002-E(VG 32, 46)

• Eaton M-2950-S/Vickers I-286-S3(VG 68)

• JCMAS P041 HK Normal Temperature(VG 32, 46)

Customer benefits

Special anti-wear additive package reduces wear by protecting surfaces when applied load causes breakdown of the lubricating film.

Reduced downtime

Effective rust and oxidation inhibitor system prevents

- the production of abrasive particles from rust & deposits

- varnishes and sludges from oil breakdown which can damage equipment surfaces & seals

- filters being blocked prematurely

Trouble-free operation

Good hydrolytic stability and water separation characteristics provide excellent filterability in the presence of water contamination. Good anti-foam and air release properties ensure smooth operation and system efficiency.

Extended oil service life

High oxidation stability resists oil thickening and deposit formation in service, eliminating the need for unscheduled change of hydraulic fluid.

Main characteristics

Specific Gravity, 15°C : 0.875

Kinematic Viscosity, mm2/s @ 40°C : 149.2

Kinematic Viscosity, mm2/s @ 100°C : 15.5

Viscosity Index: 106

Pour Point °C : -32

Flash Point °C : 245

Rust Preventive, Sea Water (D665): Pass